Optical system devices need to be able to meet the requirements of high rigidity, high strength and high stability, so as to be able to withstand harsh mechanical and thermal environments and ensure optical performance. Although the traditional optical component manufacturing process has reached a very high technical level, it is still a labor-intensive industry, and there are still challenges in ensuring the performance of the optical system.

Additive manufacturing technology can simplify the manufacturing process of optical devices, shorten lead times and reduce material consumption. More importantly, additive manufacturing technology can realize optimized design solutions for functional integration, especially in the field of satellite optical system manufacturing. Additive manufacturing technology can meet the growing needs of users for light-weight optical systems and realize the next generation of high value-added optics. Device manufacturing.

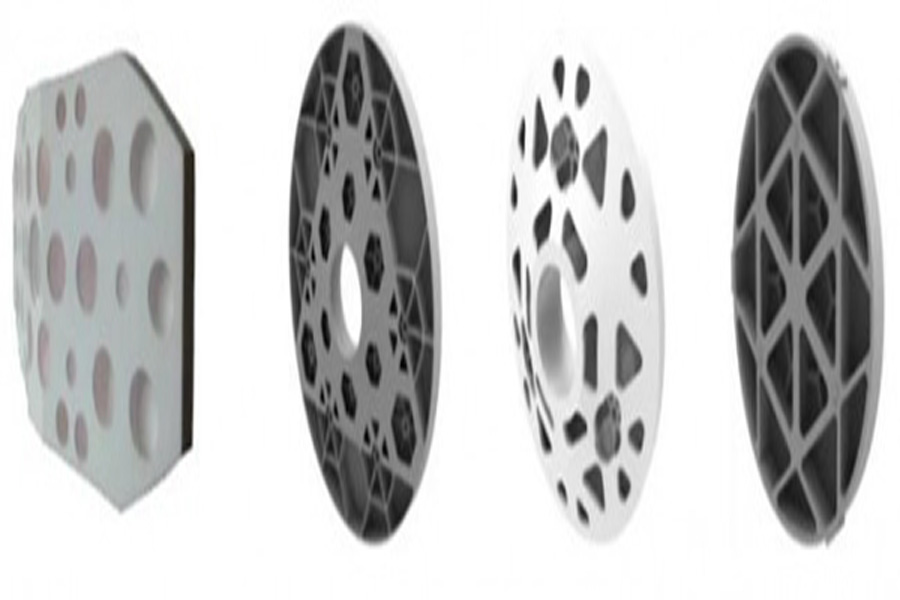

Ceramic 3D printing company 3DCeram has developed 3DOptic, an additive additive manufacturing process that optimizes ceramics to optimize optical substrates based on its light-cured ceramic 3D printing technology, and uses this process to develop optical mirrors required in nano-satellite telescopes. Optical system designers can explore innovative designs of satellite ceramic optical mirrors through the 3DOPTIC process, including semi-closed back structures, integrated interfaces, and conformal ribs.

Next-generation satellite optical mirror

In the next generation of optical instruments developed through additive manufacturing technology, more and more compact functional integrated designs will be adopted, such as integrated heat insulation, cooling channels, limited mechanical and thermal interfaces, and optical functions as part of the device’s own structure . The compact and integrated design reduces the risk of problems during the assembly process and opens up new ways to manufacture cooling optical systems, active optical systems or free-form surfaces. The net shape capability of ceramic additive manufacturing technology can also improve accuracy and improve the quality of the integration/bonding process. Ceramic 3D printing is only one step in the process, and the successful completion of the additive manufacturing of parts is also related to the professional knowledge in the support post-processing, degreasing and sintering steps.

The following is the zirconia ceramic 3D printed mirror installed in the nanosatellite telescope.

The red component is 3D printed from TA6V titanium alloy, and the 3D printed ceramic mirror can be easily assembled with it.

The technical advantages that the additive manufacturing process brings to the manufacture of satellite optical mirrors include:

- Optimization of quality/stiffness ratio (the thickness of 3D printing ribs is limited to 0.2mm; machining is 1mm);

- New mechanical and thermal functions, such as sealing channels or compliance mechanisms;

The advantages of additive manufacturing in the manufacture of next-generation optical devices are being verified in application practice. The following two cases demonstrate the ability of additive manufacturing technology to achieve weight reduction and complex designs.

l. Reduce weight by 73%, but maintain performance

The European Space Agency (ESA) supported a new additive manufacturing research project. The research team of the project redesigned the space telescope and fabricated the telescope components using metal 3D printing technology. The redesigned space telescope consists of three main parts, including the two mirrors of the telescope, both made of flight-grade aluminum alloy. The original design version of the telescope is the ozone monitoring (OMI) telescope used in the EOS-Aura mission of the National Aeronautics and Space Administration (NASA). This telescope weighs 2.8 kg, while the redesigned 3D printed telescope weighs 0.76 kg, which reduces 73%, and the quality of the measurement is not reduced.

2.5G ceramic beamforming antenna lens

Another ceramic 3D printing technology based on nanojet technology is used in the manufacture of 5G beam shaping lenses to achieve a design that includes many hollow spherical spheres, which overcomes the development challenges of 5G beam shaping antenna lenses. The lens antenna can be installed on top of a series of small antenna feeds, and the antenna feed array is connected to the beam switching circuit. Each cavity in the sphere is located at the top of the antenna feed and serves as a waveguide at the correct angle in the hemisphere, which can support simultaneous multiple beams.

The light-cured ceramic 3D printing process used in the case of satellite optical mirror manufacturing in this article is currently the best ceramic additive manufacturing process. According to the market research of 3D Science Valley, in the medium and long term, the added value of 3D printed ceramic parts will drive users’ demand for ceramic additive manufacturing hardware and materials. Many companies that produce ceramic components, especially those that manufacture advanced ceramic components, can benefit a lot from high value-added ceramic components designed for additive manufacturing (DfAM). But companies still need to cultivate the additive manufacturing thinking of developing truly high value-added components. The satellite ceramic optical mirrors shared in this issue and the above cases all use design thinking for additive manufacturing, which brings some inspiration to users in the ceramic field to cultivate additive manufacturing thinking and use 3D printing to develop high value-added ceramic parts.