Tissue engineering or regeneration is the process of improving or replacing biological tissues by combining cells and other materials with optimal chemical and physiological conditions to build a scaffold on which new living tissue can be formed. We have seen many examples of 3D printing used to accomplish this task. The potential to modify new tissues in this way provides answers to the shortage of organ transplants and their applications in drug discovery.

However, to become a viable tissue, these cells need oxygen delivered to them through blood vessels. In the transplanted tissue, oxygen may take several days to grow. But a group of researchers is working on a solution: a bio-ink that can release oxygen, which can deliver this most important element to the cells of 3D bioprinted tissue. In this way, cells can survive while waiting for blood vessels to grow.

The heart cells (L) in the bio-ink are not supported by oxygen, while (R) has the function of releasing oxygen. Live cells are stained green, and dead cells are stained red.

The most recent research teams are from UCLA, Kocaeli University in Turkey, Terasaki Institute of Biomedical Innovation (TIBI) in California, Sharif University of Technology in Iran, Erciyes University in Turkey, University of Lorraine in France and University of Iowa. Published a paper about his work in Advanced Healthcare Materials, “Bio 3D Printing of Gelatin Methacryloyl Structure of Oxygenated Cells”.

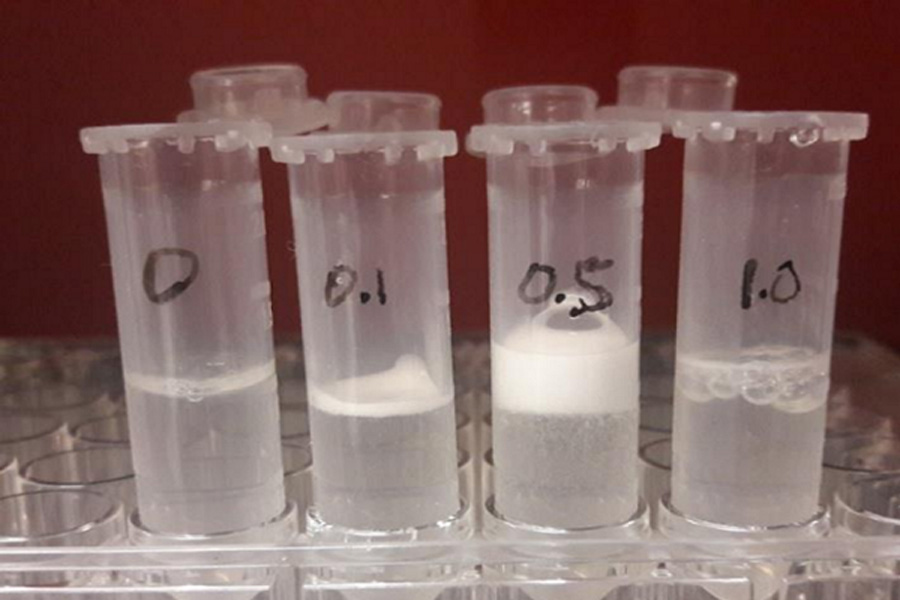

The abstract states: “The survival of cells in the early stages of transplantation and before the formation of new blood vessels is the main challenge for bio-printed tissues in translation applications. O2 generation sources such as calcium peroxide (CPO) are used to supplement oxygen to the transplanted cells. (O2) is an attractive method to ensure cell viability. Calcium peroxide also produces calcium hydroxide, thereby reducing the viscosity of the bio-ink, which is a limiting factor for bio-printing. Therefore, the solution is adapted to bio-3D Printing is very important. In this research, a gelatin methacryloyl (GelMA) bio-ink that has been optimized in terms of pH and viscosity was developed. The improved rheological properties lead to a suitable 3D bioprinting and controlled O2 release In addition, the O 2 release, bioprinting conditions and mechanical properties of hydrogels with different CPO concentrations were characterized. As a proof of concept study, CPO containing GelMA bioink was used for fibroblasts and cardiomyocytes. Bioprinting. Check the viability and metabolic activity of printing cells after 7 days of culture under hypoxic conditions. The results show that under hypoxic conditions, the addition of CPO can improve the metabolic activity and cell viability of the cells in the bioprinted structure.”

It is understood that in order to enhance the physical and chemical properties of its oxygen-generating gelatin methacryloyl (GelMA) bio-ink, the team conducted extensive tests and found that enough oxygen was delivered to the cells to maintain the developing tissue structure , Until the blood vessel is completed. develop. Once this happens, the container can take over the delivery of oxygen. Even then, bio-inks can still help by providing additional support to enhance the growth and regeneration of more new tissues.

Dr. Samad Ahadian, the lead researcher of the TIBI team, explained: “By delivering oxygen to the implanted cells, we will be able to improve tissue function and integrate it into the host tissue. Similar methods can be used to make functional tissues have longer survival. In order to carry out drug screening and pathophysiological research over a long period of time.” In addition, the researchers conducted experiments on tissue structures with two types of cells (including muscle cells and heart cells), and reported the use of new The bio-ink will produce some “positive effects.”