New energy vehicles put forward higher requirements for working conditions, and the entry point for 3D printing technology to manufacture new energy vehicle parts is lightweight and thermal management. In the field of vehicle thermal management, a relatively conventional way of heat dissipation is to use a low-cost and effective radiator to passively cool the airflow, which can be achieved through traditional processes.

However, this passive heat dissipation method is difficult to meet the heat exchanger requirements of the battery system of new energy electric vehicles. This is because the battery system in an electric vehicle provides electricity for the entire vehicle and requires an active cooling system with input cooling liquid. Powder bed fusion (PBF) additive manufacturing technology makes it possible to manufacture a new generation of compact and efficient heat exchangers. If metal 3D printing technology is combined with copper with excellent thermal conductivity, it will be an improvement in electric vehicle heat exchanger technology. Bring huge room for imagination. However, the excellent thermal conductivity, reflectivity, and high ductility of copper metal materials also pose challenges for additive manufacturing and post-processing, and also increase the application difficulty of copper 3D printed heat exchangers.

But these challenges have also become a driving force for the improvement of additive manufacturing of copper metal materials and the improvement of printing processes. In this issue, 3d-printing-china.com will discuss with you several factors that promote the application of copper 3D printing.

Diversified development of copper metal additive manufacturing technology

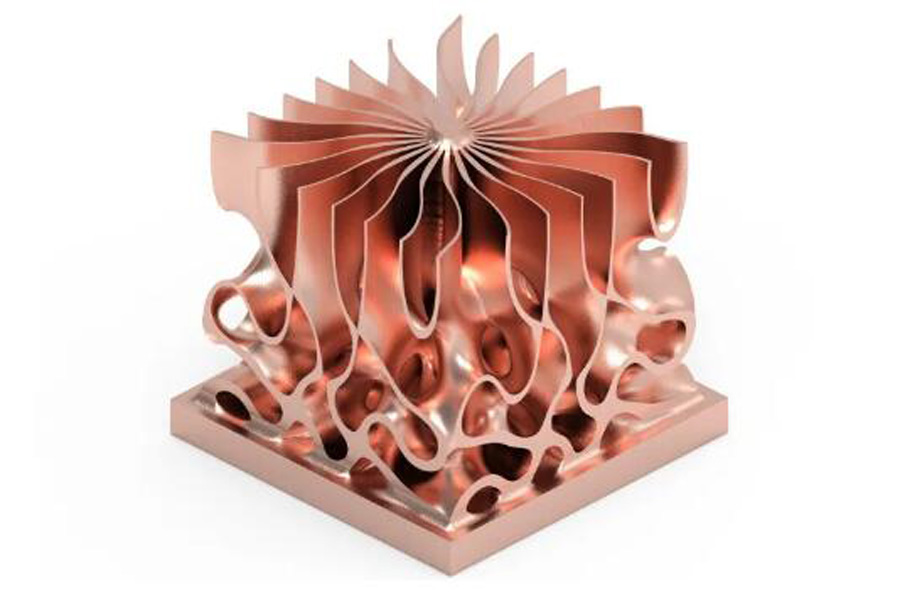

Metal 3D printing technology based on the powder bed melting process can realize complex designs and release design freedom. The application of this technology in heat exchanger manufacturing enables designers to use advanced design strategies, such as the use of gradients and variable density. The lattice structure increases the surface area of the heat exchanger in a limited space and improves the heat exchange performance. In short, the design for additive manufacturing can realize the use of higher-density structural materials in locations with high thermal loads, thereby achieving a balance between lightweight and cooling performance.

Pure copper has excellent thermal conductivity and is an excellent material for manufacturing heat dissipation components. Its applications cover a wide range of fields from microelectronics to injection mold inserts.

Based on the above two points, it is not difficult to understand that if copper with excellent thermal conductivity can be combined with advanced heat exchanger design for additive manufacturing, it will bring more possibilities for the manufacture of lightweight and high-performance heat exchangers.

However, there are challenges in practical applications. Due to the excellent thermal conductivity and reflectivity of copper, this makes it difficult to handle copper metal inside the 3D printer. Especially in the selective laser melting 3D printing process, the absorption rate of copper metal in the laser melting process is low, and it is difficult for the laser to continuously melt the copper metal powder, which leads to problems such as low forming efficiency and difficult control of metallurgical quality. In addition, the high ductility of copper makes post-processing tasks such as removing excess powder more difficult. Therefore, despite its excellent thermal conductivity, copper has not become the material of choice for additive manufacturing.

However, in the development and changes of copper metal additive manufacturing technology, the combination of copper and advanced additive manufacturing design has a higher feasibility.

1. Laser changes

The lasers used in most selective laser melting 3D printing systems on the market have low copper absorption rates, so high-power lasers must be used, but this will increase recoil pressure, vaporization, splashing and related defects. [1] However, the good news is that the emergence of new lasers has improved the detail resolution of copper additive manufacturing and the ability of pure copper additive manufacturing.

The Fraunhofer ILT Institute in Germany carried out the “SLM Green” project and found that compared with existing methods, the “SLM Green” project aims to “significantly improve the resolution of details and be more cost-effective”. The most distinctive feature is that the color of the laser is green.

According to Fraunhofer ILT, the laser used in the current powder bed laser melting technology usually operates in the infrared spectrum of light, which is why the low absorption rate of copper occurs, and the energy of light cannot effectively melt copper metal. In the green laser, it is shorter than the 1μm wavelength, and the wavelength is 515nm. This means less laser power output, and in addition, the laser beam can be more precisely focused, enabling it to use the new SLM process to manufacture finer parts. Fraunhofer ILT is creating more uniform melt pool dynamics in order to build components with high material density and achieve higher detail resolution.

In 2018, Shimadzu Corporation intends (Japan) to commercialize its BLUE IMPACT blue impact diode laser, which can generate 100 watts of power at high brightness. This product was developed by Shimadzu Corporation in cooperation with Osaka University, Japan, and is part of a Japanese national project.

The BLUE IMPACT laser incorporates many gallium nitride (GaN) blue laser diodes from Nichia Chemical Corporation (Japan). Since 2006, the efficiency has doubled and the output power has increased by an order of magnitude. A key application of Shimadzu’s 450nm blue diode laser is the 3D printing of copper materials.

Copper has a high absorption rate for blue lasers, and the reduction of back reflection can make the processing process faster, which is a severe challenge to traditional infrared lasers. The newly developed 3D printer can print objects efficiently with pure copper powder.

2.Additive manufacturing of copper alloy materials

In the common selective laser melting 3D printing process, copper alloy powder is generally used instead of pure copper, such as CuCrZr, CuNi3Si and so on. The copper alloy material allows the use of commonly used red lasers for melting.

The proportions of copper alloy components can achieve customized material properties by balancing electrical conductivity and porosity. Copper alloy 3D printing materials and processes based on selective laser melting process have been developed in recent years.

The application of copper alloy 3D printing technology has been developed in the field of rocket engine manufacturing. Launcher, a small rocket manufacturer, has cooperated with 3T and EOS to develop 3D printed copper alloy rocket engine parts. The material is Cucrzr. This engine integrates complex cooling channels. This design will improve engine cooling efficiency. This application reflects the improvement of thermal management performance brought about by the combination of copper alloy and the complex design of additive manufacturing.

Metal 3D printing company SLM Solutions has verified and passed a copper alloy material-CuNi2SiCr for selective laser melting 3D printing, and established the ideal printing parameters of this material. The copper alloy CuNi2SiCr is a heat-hardenable alloy featuring high rigidity and a balanced combination of electrical conductivity and thermal conductivity. The alloy includes nickel and silicon components and has high corrosion resistance and wear resistance.

3.Diversified pure copper 3D printing technology

Powder bed electron beam melting:The ability of copper to absorb energy varies with the wavelength of the energy source. According to GE’s description, pure copper absorbs 80% of the energy from the electron beam melting process, while it only absorbs 2% of the energy in the red laser beam. In terms of melting capacity and ultimately increased productivity, this provides advantages for powder bed electron beam melting (EBM) 3D printing. Without affecting the high electrical conductivity or thermal conductivity, the ability to produce unique and complex geometries from pure copper is suitable for many fields, including the automotive industry or the electrical connectors, induction coils and heat exchanger applications that are being sought.

There is still room for further improvement in pure copper additive manufacturing. According to market observations by 3d-printing-china.com , researchers from the US SLAC National Accelerator Laboratory, North Carolina State University and other institutions are improving the surface quality of copper powder and electron beam melting (EBM) 3D printing technology to overcome additive manufacturing of pure copper materials. Challenges in the field.

During their research, they designed a blaster tube assembly that integrates internal cooling channels. The blaster tube is a special vacuum tube that can amplify radio frequency signals. The heat transfer performance of this functional integrated assembly is improved. For accelerator applications, copper usually needs to meet or exceed the requirements of ASTM F68 for Class 1 Oxygen-Free Electronic (OFE) copper. These devices require extremely high quality and pure materials to avoid part failures (such as cracks or vacuum leaks) .

The research team first improved the surface quality of the material, using finer copper powder and changing the fusion of the layers. However, the use of finer copper powder allows more oxygen to adhere to the copper powder, increasing the oxide in each layer and reducing the purity of the printed object. The research team needs to find a way to reduce the oxygen content in copper powder. The method they use is to combine oxygen into water vapor through hydrogen and drive it away from the powder. The research team said that in the traditional manufacturing of copper parts, the formation of water vapor will generate high-pressure vapor bubbles inside the material, and the material will bubble and rupture. However, in the additive manufacturing process, water vapor escapes layer by layer, which can be more effective. In order to effectively release water vapor.

Markforged has launched a copper printing solution for its metal X printer that makes 3D printing pure copper very simple. With the Markforged Metal X system, users can easily manufacture complex parts with high electrical and thermal conductivity that were previously expensive, time-consuming or impossible to manufacture. Markforged copper material contains more than 99.8% pure copper, which has excellent thermal and electrical conductivity and high ductility.

Different from the selected area laser metal melting 3D printing process, the 3D printing copper metal process developed by Markforged mixes copper and plastic materials into copper wires, and then constructs parts layer by layer by extrusion and melting. This process is only melting the plastic, and It’s not melting copper. Then, put the copper into the sintering furnace to remove the plastic material.

The 3D printing copper metal process developed by Markforged is expected to solve the challenges of casting and brazing of cast copper parts for electric vehicles, replacing casting and brazing, and realizing more economical, more complex and efficient production of copper parts, which is expected to be applied to rotors, Manufacture of parts such as radiators and inductors.

With the help of these technologies, the additive manufacturing of copper alloys and pure copper has become more mature, and has paved the way for the manufacture of high-performance copper metal heat exchangers. Combined with the design for additive manufacturing, it will accelerate the innovation of heat exchanger products in fields such as new energy vehicles.