If you want to choose a suitable material for your 3D printer, you must first understand the characteristics of the 3D printing material. The characteristics of each 3D printing material are different. You should first consider the material characteristics of the product you need, and then select the suitable material. Targeted printing. Here are the characteristics of five commonly used 3D printing materials.

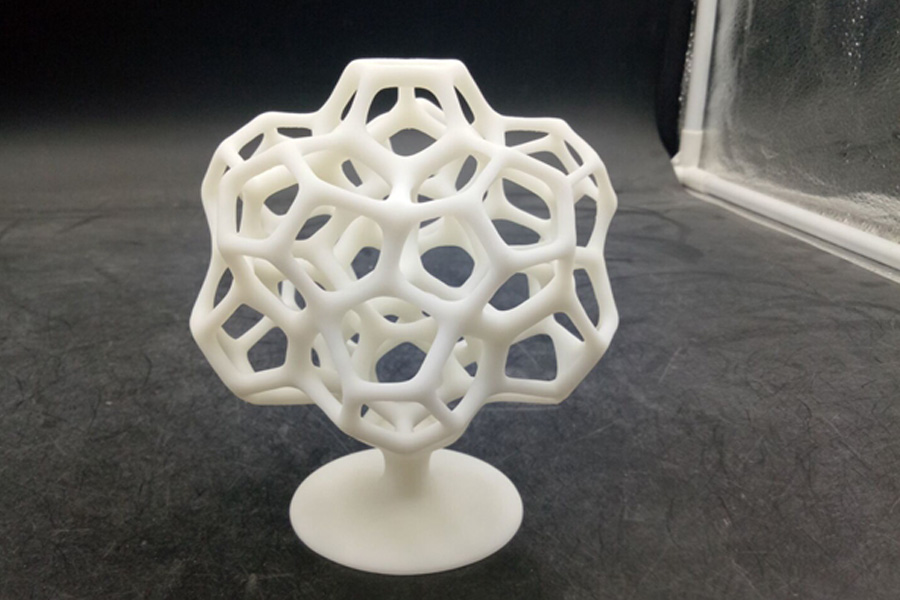

Photosensitive resin:

This material has the highest printing accuracy, usually 0.05mm. The surface is also very smooth, suitable for printing appearance parts, and it is also the only choice for 3D printing for mold opening size inspection. It can be divided into two types: ordinary resin and tough resin. Ordinary resin is white, weak in strength, easy to break, and will turn yellow after a long time, so if it is an appearance part, it is best to do color treatment. Tough resins are usually emerald green or light yellow. Compared with ordinary resins, tough resins have slightly better strength and are not easy to break. It is worth mentioning that: if you use resin materials for structural parts, do not tap threads on them, and do not use tight matching methods to insert nuts, which will burst the holes.

White photosensitive resin

PLA: The printing cost of this material is relatively low. If it is used for temporary structural display, it can be made with this material if the appearance is not high. The material strength is high, and the printing process can easily optimize the filling rate inside the structure, so it is very easy to achieve lightweight. The accuracy is slightly weaker. If the parts have a matching relationship, be sure to leave enough space to ensure assembly. Usually the shaft hole is matched with at least 0.5mm gap. When designing, it is necessary to minimize the structure suspension, because the suspended structure part needs printing support, it will be rougher. The material has a deformation temperature of 60 degrees and cannot be used in a high temperature environment.

PLA consumables

TPU: Soft rubber material, rich in color, can print parts such as car wheel, shock-absorbing pad, sealing ring and so on. The hardness is between 80A and 95A. The surface of the printed product is smooth and shiny. After printing, parts with complex structures are more severely threaded, and the surface is hairy, making it difficult to handle cleanly. If the surface requirements are very high and it can be done in a complex mold, it is to print the resin prototype first, then wrap it with silicone to make a mold, and finally use a similar casting method to make a TPU part. The process is more complicated. The cost is high, the effect is good, and it can be used to make complex parts such as watch straps.

TPU elastic material

ABS: Common engineering plastics, with the characteristics of heat resistance, impact resistance, low temperature resistance, chemical resistance, good electrical properties, and product dimension stability. The heat distortion temperature is 93~118℃, it can still show a certain degree of toughness at -40℃, and can be used in the temperature range of -40~100℃. Suitable for structural parts.

nylon:

The strongest material among non-metallic printing materials is nylon. The best process for printing nylon at this stage is SLS laser powder sintering. The molding accuracy is very high, and the strength and toughness of the obtained workpiece are also the best. In addition, the nylon material itself is also resistant to high temperature and wear resistance, and is suitable for structural frames. The surface of the parts obtained by laser sintering has a matte texture, which can eliminate the need for surface treatment.