With the continuous development of science and technology, the structure of parts is becoming more and more complex. When using traditional casting technology to produce parts, the design and manufacture of molds will spend a lot of time, increasing the production cycle and R&D costs.

The use of additive manufacturing technology can directly form complex-shaped sand molds through computer-aided design models, which has a huge impact on the foundry industry. But at present, 3D printing of sand molds is mainly to improve efficiency and reduce costs, and it does not have much impact on the performance of castings.

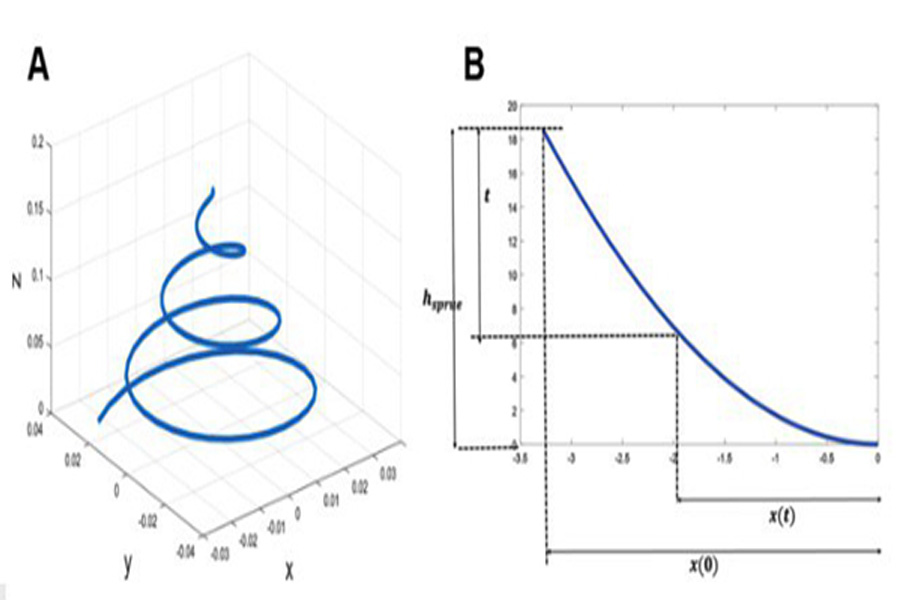

Recently, Santosh Reddy Sama and others from the School of Mechanical and Nuclear Engineering of Pennsylvania State University proposed a design criterion for complex gate system based on 3D printing technology to improve the casting performance of castings. The working principle of this technology is: for the given pouring conditions, calculate the conical spiral and parabolic gate contour data based on Bernoulli equation, and use the constrained optimization algorithm to obtain the optimal gate contour shape with the contour parameters.

When designing the gate profile shape, it should be based on the casting fluid dynamics so that the gate profile shape meets three conditions to reduce casting defects. First of all, the velocity of the fluid at the bottom of the gate should be less than the minimum critical velocity (0.5m/s); secondly, the length of the gate should be minimized to reduce heat loss and allow sufficient time for the generated bubbles to escape the mold; finally, it should be avoided A sudden change in the cross section of the gate or the cross section at the junction of the gate and the runner.

The researchers used the Viridis3D RAM printer to make different gates and molds, where the layer thickness is 0.4mm, and the raw materials are Viridis3D produced Viricast powder and CSTRed adhesive. Cast the 17-4 stainless steel alloy at 2950°F to obtain the part (as shown in Figure 2).

Three samples were tested (as shown in Figure 3). In the figure, AD is the microscopic morphology of the sample. The round black dots are oxide inclusions formed by the surface turbulence of the melt during the filling process. Observation shows that compared with straight gate castings, the inclusions of parabolic gate castings and conical spiral gate castings are reduced by 21% and 35%, respectively. E-H is the computer tomography of the sample. It can be seen from the figure that, compared with straight gate castings, parabolic gate castings and conical spiral gate castings have reduced casting defects by 56% and 99.5%, respectively. Comparing the ultimate flexural strength of the three samples (as shown in Figure 4), it can be seen that, compared with the straight gate casting, the strength of the conical spiral gate casting is increased by 8.4%, and the strength of the parabolic gate casting is increased by 4.1%.

Therefore, 3DP technology can be used to manufacture special-shaped gates that are difficult to manufacture by conventional methods, such as parabolic gates, conical spiral gates, etc., which can not only greatly reduce casting defects such as inclusions, improve the yield of castings, but also greatly Improve the mechanical and metallurgical properties of castings.