The Fraunhofer family of German research institutes continues to invent novel manufacturing methods and auxiliary technologies. This time is the latest product of the Fraunhofer Institute for Ceramic Technology and Systems (IKTS). It is a multi-material inkjet system that can 3D print multiple metals or ceramics in a single structure. To prove this process, Fraunhofer IKTS researchers 3D printed a ceramic satellite with a built-in ignition device.

This technology is similar to the existing polymer inkjet 3D printing technology, such as Stratasys’ PolyJet. However, it starts with mixing ceramic or metal powders into thermoplastic binders. This slurry is then melted in a micro-dosage system at a temperature of about 100°C, and then deposited at a rate of up to 60 mm, depositing 1,000 drops per second, with a droplet size ranging from 300 to 1,000 μm, and the number of layers formed The height of 100 is 200μm. The part size can reach 20×20×18 cm (7.87 inches x 7.87 inches x 7.09 inches).

Fraunhofer IKTS researcher Uwe Scheithauer explains: “The key factor here is the custom dosing of metal or ceramic slurries. The correct dosage is to ensure that the final product of additive manufacturing has the The key to the required performance and function, including strength, thermal conductivity and electrical conductivity.” The software developed by the team can ensure this accuracy to ensure the precise positioning of the droplets during the printing process.

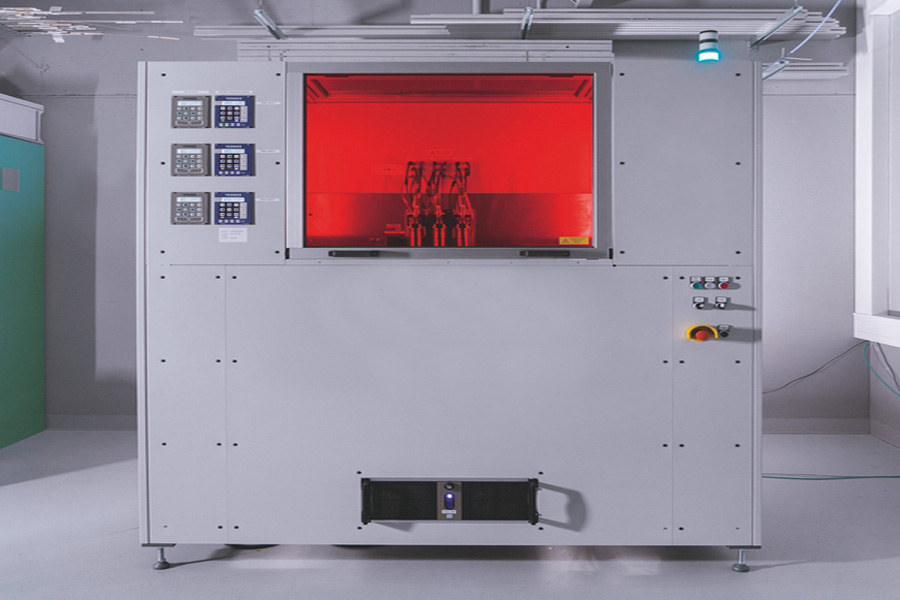

According to Scheithauer, up to four different materials can be printed at a time, allowing the production of multifunctional parts with specific physical properties. This includes the ignition system used in the ceramic satellite propulsion engine. The Fraunhofer team chose ceramics to withstand the high temperatures experienced by the combustion chamber of the satellite engine, and printed an ignition system composed of three different materials: a conductive ceramic, an electrically insulating ceramic, and an insulator. Support material that will decompose during the post-positioning process. Printing and sintering are carried out in the furnace.

The German Institute envisions other applications of the technology, including consumer products, such as two-tone ceramic watches or industrial parts made by the team for individual customers. “For example, we can also use it to make blanks for cemented carbide parts. Because the batching system has extremely high precision, the contours of the blanks are already very close to the contours of the final product. Therefore, they will require a lot of Less follow-up grinding. This is a big advantage when you use cemented carbide.”

Now that the technology has been implemented and demonstrated its scalability, the Fraunhofer IKTS team will verify it in industry. This means that in cooperation with industrial customers, Fraunhofer may help them develop materials and software for process monitoring and automation. The German Research Institute will discuss this technology at the CERAMITEC conference held online from September 16 to 17, 2020.

Comment: There is still a long way to go to achieve the ability to 3D print complete functional objects in a single manufacturing process, but Fraunhofer brings us closer to achieving this goal. Accompanying it are companies like Optomec, whose Aerosol Jet 5X system is used in the mass production of mobile phones, and startups like InkBit, which may herald the future of making custom electronic products with just one machine.