Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

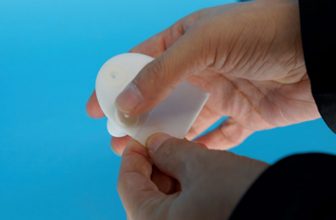

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

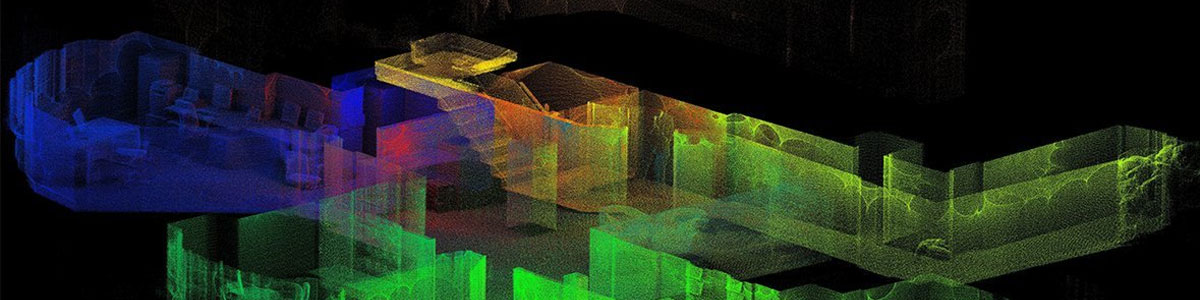

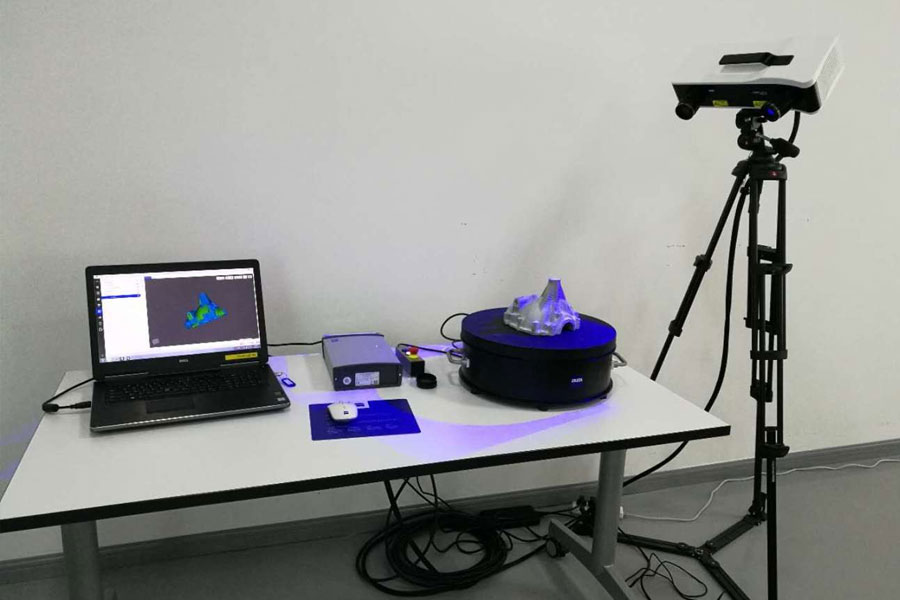

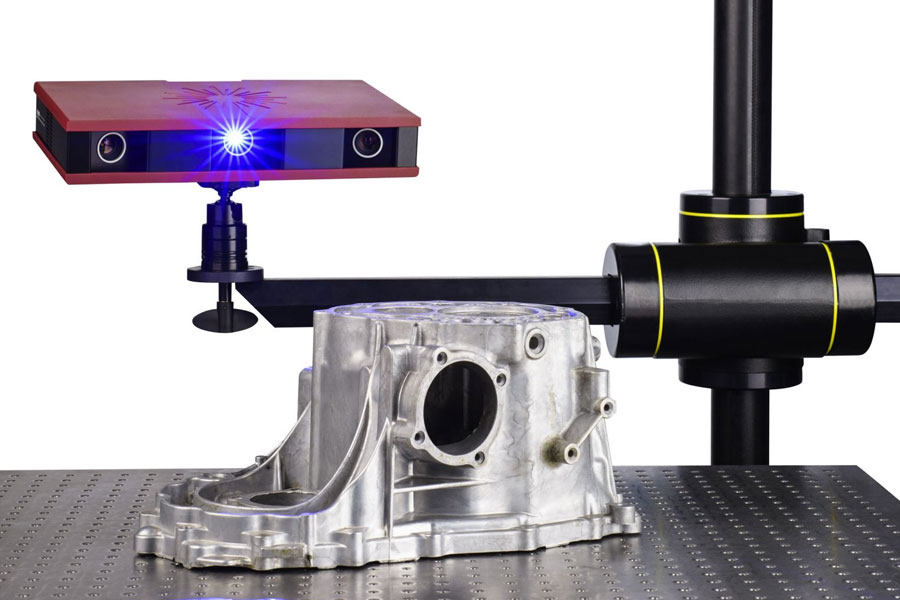

Large Scene 3D Scanning

Perfect splicing of multi-point scan data, output 3D point cloud data or 3D model

What Is Large Scene 3D Scanning?

Large-scene three-dimensional scanning is widely used in cultural relics protection, urban building surveying, topographic mapping, mining industry, deformation monitoring, factories, large structures, pipeline design, aircraft and shipbuilding, highway and railway construction, tunnel engineering, bridge reconstruction and other fields.

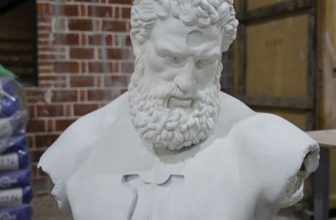

Laser 3D scanning of large scenes can reach millimeter-level accuracy. Take the protection of cultural relics as an example. Application in the protection of cultural relics: 3D laser scanning of large scenes is mainly for ruins, ancient buildings, sculptures, etc. The development of human society has left many precious cultural relics, natural and cultural landscapes. With the passage of time, these heritages have been severely weathered and become incomplete, and some have even begun to disappear. In order to protect and restore these heritages, three-dimensional laser scanning Provides brand-new technical means, can obtain the geometric and texture information of cultural relics, and store and manage digital information.

Table of Contents

The Application Of Large Scene 3D Scanning Service

The Industrial Applications Of Large Scene 3D Scanning

The three-dimensional laser scanning system can provide true three-dimensional, true-size data model of factory transformation, which can speed up the design progress and obtain the best design plan for the enterprise.

The Archaeological excavation site Of Large Scene 3D Scanning

Three-dimensional scanning technology collects the spatial structure information and construction information of ancient buildings into the computer with a data collection volume of nearly one million points per second.

The Yingxian Wooden Tower Of Large Scene 3D Scanning

In order to fully preserve the most complete and accurate three-dimensional data of Yingxian Wooden Pagoda, large-space three-dimensional scanning technology was adopted for the implementation of this project.

The accident scene Of Large Scene 3D Scanning

The 3D point cloud data can provide an intuitive scene scene for subsequent analysis. High-precision point cloud data can highly restore the on-site environment

The building structure Of Large Scene 3D Scanning

Using point cloud data to automatically detect and measure the cross-sectional dimensions of the bridge main girder and improve the efficiency of construction management.

The Large bridge structure Of Large Scene 3D Scanning

The team used three laser scanners to perform a comprehensive scan, and then formulated a feasible construction plan based on the collected point cloud data.

When To Use Large Scene 3D Scanning ?

For the 3D data collection of large-scale archaeological sites, ancient villages and historical buildings, the 3D surveying and mapping of large-scale factories, infrastructure projects, and bridge pipelines all require large-scale laser scanning equipment to provide services.

Large-size laser scanning does not require contact with the scanned object. It can perform panoramic scanning at a long distance, and can perfectly splice multi-point scanning data of the same scene, and finally output a complete 3D point cloud data or 3D model.

Many historical buildings are ancient. Some stone carvings and wood carvings have been weathered and damaged, and some beams, columns, and tenon joints have been distorted and deformed, and even many ancient villages have been on the verge of collapse. The large-scene scanning technology can be used without touching the scanned object. , Complete the acquisition and modeling of 3D data in the context of the scene, and provide perfect data support for the 3D archiving of ancient buildings, CAD data output, repair plan discussion, online display, simulation and other purposes.

With the migration of time, many large factories have made several technical improvements, and the actual factory drawings are completely different from the original drawings at the beginning of the factory. Many bridges, dams, and archways have also been deformed over time. These are hidden safety hazards. The data obtained by scanning large scenes, archiving, comparative analysis, and danger warning are of very practical significance.

The Application Direction Of Large Scene 3D Scanning

3D laser scanning technology stands out due to its high efficiency, accuracy and non-contact advantages. Its application directions for large scenes are as follows:

- – Digital factory & workshop reverse;

- – Digitization of large outdoor cultural relics;

- – Infrastructure, traditional surveying and mapping engineering;

- – Three-dimensional point cloud collection and modeling;

- – Three-dimensional data scanning of the archaeological site;

- – Three-dimensional archives of ancient villages and historical buildings;

Delivery within 30 days after the scan is completed, and a variety of data formats are available.

3d-printing-china.com Case Studies

The Peach Blossom Fan Of 3D Printing

3D Printing Funny LOGO

Large Sculpture Model 3D Printing Prototype

3D Printing High-Precision Buddha Statues

3D Printing Halloween Bat Masks

3D Printing Large Sculptures

3D Printing Moon LED Lights

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.