Guide

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

- Common Technology List Of Metal 3D printing

- 3D Printer Tutorial: Answers to Frequently Asked Questions for Users

- What Is DFAM

- The nine common photosensitive resin 3d printing materials

Case Studies

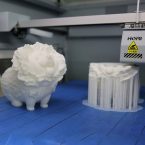

3D Printing Moon LED Lights

- Product name: Moon LED Lights

- No+Color:Custom

- Surface treatment:Custom

- Product material: 3D Printting Material

- Proofing cycle:7 days(100000 pcs/M)

- Application:Art Design

- machining factory:3d-printing-china.com

- Product Category:Art Design

- Production Process:3D Printing

- Size:According To Customer Drawings

High-Quality Custom 3D Printing Moon LED Lights

Balloon type mobile lighting (also known as: moonlight) 360-degree shadowless lighting, powerful and soft halogen light source; built-in fan, rapidly expanding the balloon; four power supply modes: AC, DC, generator, and on-board, loss of voltage and power failure The protection system is safe and reliable; the original bracket cooperates with the electric lifter to operate flexibly; flame-retardant and wind-resistant; light and easy to transport. It is the most ideal lighting work for search and rescue sites. It can also be widely used in photography sites, exhibition venues, temporary venues, and open air. Concerts, sports fields and tourist hot spots can also be used in industrial production sites that require continuous day and night operations, such as open-pit mining and major construction sites.

3d-printing-china.com Supply ISO 9001:2015 certified additive manufacturing services including Moon LED Lights 3D printing services. 3D printing services are available. Prototyping, tooling design and fabrication services are also available.

This 3D printing case study involves a lunar lamp, which is extremely compact and easy to disassemble and portable. The main body is equipped with a bulb and a reflector, and the bottom surface is provided with inner and outer card holes. The inner side is provided with a bulb holder; the reflector has a lamp hole on the end edge to allow the bulb to be inserted; one end of the frame cover has a gap and a hook; the lampshade is assembled with glass, and the inner side of the lampshade is equipped with threads, which can be screwed into the frame. Cover; the shell is a ring-shaped shell, the inner edge is provided with a fixed hook, and can be hooked on the outer hole of the main seat, which can make the overall assembly more convenient, and has a layered visual effect of the shape.

Advantages of Our High-Quality Custom Moon LED Lights

The 3D printed three-dimensional moon lamp is a kind of desk lamp. As the name suggests, its shape resembles the moon. Its biggest feature is that the moon is prototyped in proportion, and it is 3D printed and molded. With the help of the relief on the surface of the lamp, the thickness and transmittance of the lunar surface are different. Concave-convex light and dark, the effect is extremely vivid, it is an innovative exploration of 3D printing technology in the field of lamps and lanterns. Light sources include ordinary white bulbs, fluorescent lamps, LEDs, etc. Integrating lighting and viewing, mainly LED lunar lights are used for lighting, decoration, viewing, and photography.

- – SLA/SLS/3D printed parts are fully dense, incorporating complex geometries and precise internal features.

- – Designs can be made quickly with a minimum of material waste while maximizing strength.

- – Multiple, identical parts can be built on a single platform at one time, greatly increasing production efficiency

- – Accurate to drawing parts & High quality surface treatments

The Advantage Application Of Moon Led Lights

Advantage application:

- lighting: warm yellow light for eye protection, the best lighting tool for study and bedroom, especially suitable for children’s bedroom, protect eyes and promote sleep; PLA organic material is green and non-polluting, comfortable and refreshing, LED energy-saving lamps save energy; camping Essential, long-lasting wireless charging, easy to carry. The night is quiet, or a bonfire is raging, or a whisper, accompanied by a bright moon, enjoy the warmth, burn out the moonlight, and bloom in the dark night!

- Gift: If she pays attention to the taste of life and pursues style, if she is full of imagination and loves to create, if she likes fashion and full of literary atmosphere, give her (him) a moon lantern, “Ask me how much I love you, the moon represents My heart.”

- Decoration: Elegant moon shape, stylish and simple. Under the modern light decoration and heavy decoration concept, the moon lamp will embellish the beauty of your life and add a bit of romance to the room.

- Photography: From the birth of the bright moon at sea to the invitation to the bright moon with a toast, how many people make their thoughts to the moon but can only be empty to the moon. It is so cold and inaccessible, and now photographers can use 3d prtinting moon lights to take pictures of their hearts The beauty of the scene, depicting scenes of dim and tranquil scenes, moon lights, add unlimited imagination to your masterpiece.

The Highlights Of Moon Led Lights

Highlights: 360° three-dimensional reproduction of the appearance of the moon, giving you a moon you can hold in your arms. Accurate modeling based on the data collected by the lunar exploration satellite, which is printed by the latest 3D printing technology FDM printer. The printing accuracy is less than 0.2mm. It takes 15 hours to print a single lunar lamp body, giving you a better and rounder moon. The wish of the poets to “pick the stars” will no longer be an extravagant hope.

Specifications of High-Quality 3D Printing Moon LED Lights

| Material | thermoplastics, polycarbonate, ASA, nylon12 CF and Ultem® resin |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom (Anodized, powder coating, etc.) |

| Main Process | SLA/SLS/FDM 3D Printing |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Custom Moon LED Lights |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

Technology: CNC machining, 3D printing, rapid prototyping SLA/SLS/FDM/SLM

Process flow:

1. Order plan customization

2. Dismantling plan programming

3. Preparation

4. CNC machining

5. QC testing

6. Surface treatment

7. QC quality inspection

8. Finished product shipment

Equipment: CNC machining center, laser forming SLA machine, laser forming SLS, 3D printer, CNC lathe, CNC engraving and milling machine, milling machine, drilling and tapping machine, sand blasting machine

Capacity: 1000 PCS/days

Drawing format: IGS, STP, STEP, PRT, XTL

Material: Aluminum alloy, zinc alloy, magnesium alloy, titanium alloy, steel, copper, stainless steel, sheet metal, ABS, PC, PE, POM, PP, acrylic (PMMA), nylon, bakelite, silicone rubber

Surface treatment: Grinding, polishing, silk screen, electroplating, UV, oxidation, wire drawing, laser engraving, sandblasting, leather grain, surface etching, rubber coating, transfer, bronzing

Quality control:

1. Material quality inspection

2. Accuracy quality inspection

3. Appearance quality inspection

4. Functional quality inspection

5. Structural quality inspection

6. Surface treatment quality inspection

7. Packaging quality inspection

Test Equipment: Three-coordinate measuring instrument, 2.5-dimensional measuring instrument, inner diameter micrometer, outer diameter micrometer, electronic height gauge

QC process: 3MM standard

Delivery Time : 1-10 days

Product packaging: Inner

packaging: foam, plastic, paper;

Outer packaging: hard thick cardboard boxes, custom wooden boxes

Cooperation Process:

1. Provide samples/documents

2. Customer service quotation

3. Confirm order

4. Processing

5. Package delivery

6. Confirm receipt

Sign NDA

We sign the NDA with our customer and also for their projects. Each employee must take pre-enter company training to follow our production flow, so that keep company information security. NDA will be signed on board date. As well as for all our suppliers have to sign NDA. For date security, we use the ISO27001 as the reference. All the data will be securely kept at our own network centre, only the authorized staff can access to the centre and review the data.

Flow Production

We use the work order system to control each process step, timeline for each job is very clear for each team. All of customer requirements will be reflected from the work order. When quoting, our production engineers will review the data and requirement, and provide the DFM if needed. During the production, we guarantee the on-line and off-line inspection to ensure that the parts we produce meet your exact specifications.

Quality control

We are ISO 9001 certified, first article inspection, also support to provide the FAI report.Before the packing, we have the final inspection, which will check all the quality details by our QC. We are very concerns the safety packing. For different sizes and materials production,we will adopt different packing methods to keep products delivery safely. Parts will be marked with labels of item no. and PO no. for customers to recognize easier.

Advantages Of China 3D Printing

Nowadays, 3D printing is developing in a more efficient, intelligent and rapid direction in prototypes industry. Also, 3D printing technology is becoming a trend and is slowly becoming a new way to change industries.

With the gradual arrival of the era of the big industry, the manufacturing industry is rapidly developing in a more efficient, intelligent and rapid direction. What are the advantages of 3D printing? Please see blow:

- 1. SLA/SLS/3D printed parts are fully dense, incorporating complex geometries and precise internal features.

- 2. Designs can be made quickly with a minimum of material waste while maximizing strength.

- 3. Multiple, identical parts can be built on a single platform at one time, greatly increasing production efficiency

- 4. Accurate to drawing parts & High quality surface treatments

According to the structure and quantity of the parts, the rapid processing technology is adopted. PTJ can use typical low-cost rapid production tool technology to realize small batch production, so that customers’ products can be quickly listed in the most economical way.

What kind of drawings did you receive?

We can receive local Proe (.prt) files and 3D solid CAD models exported in IGES (.igs), STEP (.stp), and STL formats in other CAD systems. Two-dimensional drawings are not accepted.Does PTJ provide surface treatment services for parts?

Yes, PTJ provides comprehensive surface treatment services for plastic and metal parts. The surface treatment of plastic parts includes spray painting, silk screen printing, electroplating, laser etching, automobile skins, water transfer printing and so on. Surface treatment of metal parts such as sandblasting, oxidation, electrophoresis, etc.How is PTJ’s quality inspection done?

With the help of precision testing equipment such as 3D and 2.5D precision projectors, PTJ conducts a full inspection of each part of small batch parts and fast samples, and issues an inspection report. Batch products adopt one-time inspection and sampling inspection in accordance with ISO standard procedures, and issue a batch product quality inspection report.I have no 3D drawings. Can you provide it to me?

We can provide design services. If you need to design a 3D model, please contact us via email.Which resin can (or should) use?

When choosing a resin, designers should consider the material properties of a particular application, such as tensile strength, impact resistance or ductility, mechanical properties, molding properties, and resin cost. If you need to choose materials, please feel free to call us.What kind of drawings did you receive?

We can receive local Proe (.prt) files and 3D solid CAD models exported in IGES (.igs), STEP (.stp), and STL formats in other CAD systems. Two-dimensional drawings are not accepted.Does PTJ provide surface treatment services for parts?

Yes, PTJ provides comprehensive surface treatment services for plastic and metal parts. The surface treatment of plastic parts includes spray painting, silk screen printing, electroplating, laser etching, automobile skins, water transfer printing and so on. Surface treatment of metal parts such as sandblasting, oxidation, electrophoresis, etc.How is PTJ’s quality inspection done?

With the help of precision testing equipment such as 3D and 2.5D precision projectors, PTJ conducts a full inspection of each part of small batch parts and fast samples, and issues an inspection report. Batch products adopt one-time inspection and sampling inspection in accordance with ISO standard procedures, and issue a batch product quality inspection report.I have no 3D drawings. Can you provide it to me?

We can provide design services. If you need to design a 3D model, please contact us via email.Which resin can (or should) use?

When choosing a resin, designers should consider the material properties of a particular application, such as tensile strength, impact resistance or ductility, mechanical properties, molding properties, and resin cost. If you need to choose materials, please feel free to call us.CNC machining capacities of PTJ?

We mill and turn some parts very quickly. Typical quantities are 1 to 200 pieces and the manufacturing time is 1 to 3 working days. We provide product developers with parts manufactured from engineering-grade materials, which are applicable to the functional tests or end-use applications.

What is the production capability of PTJ? What size could my products reach?

For information on the size of parts for milling and turning and other precautions, please refer to our Milling Design Guidelines and Turning Design Guidelines.

When should I use injection molding?

Before investing in injection molding or mass production, you may want to test parts as close as possible to the manufactured parts. CNC machining and silicone molding are the best choices for this situation.

How many machines do you have?

PTJ has the CNC precision processing equipment, including CNC milling machine, CNC lathe, 3D printer (SLA, SLS, SLM), injection molding machine, hot pot press, vacuum casting machine and other precision production equipment, and has several three-dimensional, 2.5-dimensional, scribing machine and other testing equipment.

Can PTJ perform secondary processing?

Secondary processing is currently suitable for 3D printing parts, CNC parts, injection molding parts and carbon fiber parts.

What is the injection molding capability of PTJ?

We offer plastic and liquid silicone rubber molding and 25 to 10,000 small batches of overmolding and insert molding. The typical manufacturing time varies from 1 to 15 working days. Rapid injection molding helps product developers to obtain prototypes and parts suitable for functional testing or final use within a few days.

What is the typical cost of injection molding parts using PTJ?

The price is about RMB 6000, which mainly depends on the geometry and complexity of the parts. The best way to estimate the cost is to upload your 3D drawings to our website so that you can receive an interactive quoted price within a few hours. RPS can create your molds with a small part of the traditional injection cost.

What is PTJ resin for injection moulding?

We have more than 100 kinds of thermoplastic resins and accept many resins from the customers. Check a complete list of PTJ stock resins.

3D Printing Pagoda Model

Pagodas, Buddhist buildings. It was originally the place where the Buddha was buried. Because of the inherent Qibao decoration, it is called the …

3D Printing Large-scale Mr. Rabbit Model Sculpture

Large Sculpture Model Additive manufacturing services for the automotive, food and beverage, electronic, healthcare, medical, consumer, telecom, …

3D Printing Aluminum 6061 Model

Aluminum alloy, due to its natural lightweight characteristics, occupies an important place in the field of industrial manufacturing. However, with …

Personalized 3D Printing Avatar

Since human childhood, sculpture has played an important role in human material and cultural life. Although primitive sculptures were not intended to …

3D Printing Funny Small Dog As Cabbage Shape

ISO 9001:2015 certified. Funny Small Dog rapid prototyping services including 3D printing. CNC machining and finite element analysis processes are …

3D Printing Large Sculptures

Sculpture refers to ornamental objects and memorials that are carved to beautify the environment or used for commemorative significance, and have …

3D Printed Luminous Characters Word M

The so-called logo design is the design of the logo. It is the most widely used and the most frequent in the process of corporate image delivery. It …

3D Printing Electronic Signboard Logo Word

Electronic signboards are flashing or shining through electric current. The signs are hung in front of the store as signs. Signboards are mainly used …

- European Space Agency plans to extract oxygen from moondust and 3D printed metal

- Uncover The Mystery Of CNC Machining

- How to choose a suitable 3D printer?

- 3D printing materials: Introduction to 3D printing stainless steel

- Researchers are inspired by Lego to develop 3D printed self-healing “bone bricks”

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Ceramic 3D printing takes a new step in dental products

- Nano-level 3D printing of 3D printing metamaterial series

- Swire Cold Chain Warehouse Model

- 3D printed transparent composite material can protect the phone screen

- Break the temperature limit! Chocolate of any shape that can be 3D printed at room temperature

- New multi-material 3D printing combines different metals and ceramics into one part

- 3D printing solid-state lithium battery: safer, cheaper, and higher energy density

- The Accident Scene Of Large Scene 3D Scanning

- 3D Printing Flexible Electronics Materials

- What Is DFAM

- Without investment casting, how can metal 3D printing produce superalloy turbochargers?

- Metal 3D Printing Buddha Statue Sample

- AMAERO will develop 3D printing tools for the automotive industry

- The Building Structure Of Large Scene 3D Scanning

- 3D Printed Luminous Characters Word M

- The number of parts is reduced from 61 to 1, the case shows the prospect of 3D printing micro-jet engine

- Reshaping the supply chain, Daimler introduces 3D printing to save costs

- The Appreciation Of 3D Printed Hollow Model

- How 3D printing technology plays a role in exploring the extreme environment of Venus

- Accurate Inspection Of Body Sheet Metal Parts In 10 Minutes

- Application of 3D printing technology in automobile R&D and production

- Study on the long-term stability of 3D printed ceramic crowns

- The rapid upward trend and development logic of high-strength 3D printing aluminum alloys

- Six major trends in 3D printing

- Analysis of common problems in 3D printer printing

- 3D Scanning Aviation Parts

- Why should 3D printed models be supported?

- 3D Printed High-Strength Large-Size Resin Medical Orthosis

- Comprehensive understanding of 3D printing nozzles

- 3d Printing Metal Turbine

- 3D Printing Personalized Jewelry And Ring

- 3D printing empowers digital manufacturing and customized beautiful sound quality of clarinet instruments 2

- Can copper 3D printing technology become a booster for a new generation of heat exchange technology for new energy vehicles?

- The concept and basic steps of reverse design

- The application potential of continuous carbon fiber composite 3D printing in intelligent self-induction parts

- The Peach Blossom Fan Of 3D Printing

- The precautions for the selection of FDM process 3D printing materials are as follows

- Will the binder spraying of aluminum alloy materials accelerate the application of 3D printing technology in the automotive manufacturing industry?

- Metal 3D printing makes combustion more efficient

- Comparison of 3D printing white nylon and black nylon

- Comparison of 3D printing materials that can be directly used for injection molds

- Use 3D printing to make a low-cost weather station

- Talking about the role of 3D printing figure in the development of animation IP

- 3D Printing Stunning Palace Model

- Researchers use microfluidic droplet system to adjust 3D printing flexible materials

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- 3D Scanning To Detect Pipeline Leaks

- Multi-material dispensing system for ceramics and metals

- New functions, new performance, 3D printing promote the next generation of satellite optical mirror manufacturing

- 3D Printed Metal Rings And Precision Sleeves

- 3D printing empowers digital manufacturing and customized beautiful sound quality of clarinet instruments

- Application of 3D printing helmet technology in the field of helmet production

- Through these eight factors, you can choose a 3D printer that suits you.

- Introduction to the performance of gold plating and silver plating after 3D printing

- Swiss Medacta electron beam metal 3D printed implant 3D femoral cone vertebral body starts commercial

- 3D Warehouse Login

- Explore the world of 3D printing high-temperature plastics

- Eight areas of main application of 3d printing technology

- With the great changes in manufacturing technology, do 3D printing and CNC machine tools coexist or compete?

- Personalized 3D Printing Avatar

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

- Custom Luminous Chinese Character

- Improving the casting production of metal sand molds through 3D printing

- INTAMSYS high-temperature 3D printer complete production line: used to manufacture actual parts

- Metal 3D printing achieves highly functionally integrated micro-turbine core machine design

- 3D printing lightweight housing with integrated heat exchange function

- The Large Bridge Structure Of Large Scene 3D Scanning

- 3D Printing Electronic Signboard Logo Word

- 3D printing enables the entire lighting industry to personalize business models

- Researchers use inkjet technology to 3D print graphene to produce electronic devices

- 3D Printing Nylon Car Air Conditioning System Model

- Design and manufacturing are integrated, and the promise of automation begins with generative design

- What are the differences between ordinary desktop 3D printers and industrial 3D printers?

- Carbon Fiber By 3D Printing

- Explore the application of 3D printing-assisted simulation of intracranial aneurysm microsurgery

- Looking at the development trend of 3D printing from Formnext 2021

- From the laboratory to the production line, the future of 3D printing is the future of automobile lightweight

- 3D Printing Funny Small Dog As Cabbage Shape

- Global architectural 3D printing inventory, no need to move bricks to build a house

- 3D printer basic module introduction

- 3D scanning helps industrial inspection

- BMF launches micro-precision 3D printer for industrial production

- Design evolution of honeycomb ceramics and 3D printing application cases

- Case insight into the application of metal 3D printing unicorns in heavy industry

- Mold 3D printing shortens the cooling time of injection molded products by 68%?

- 3D Printing Funny LOGO

- 3D Printing Metal Octopus Model

- Cost-benefit analysis and innovative applications of 3D printing injection molds

- 3D printed porous magnesium scaffold shows potential as a bone replacement material

- How does 3D printing really gain a foothold in the manufacturing industry?

- 3D Printing Resin Dragon Pattern China Tripod

- Copper 360 Material Parts By 3D Printing

- A brief introduction to the application of additive manufacturing in the aerospace field

- Simulation releases the potential of 3D printing-additive manufacturing

- Do you really know light-curable 3D printing consumables?

- 3D Printing Saxophone Mouthpiece

- Luminous Sphere (Outdoor Cultural And Creative Works)

- What are the factors that affect the accuracy of the light-curing 3D printer model

- 3D Scanning Car Seat

- 3d Printing Exquisite Souvenir Model

- 3D printing expands application areas for tungsten materials

- 3D printing is greatly promoted through data-driven design

- Wire 3D Printing: Process, Filament, Printer and Features

- 3D Printing Aluminum 6061 Model

- Researchers create bio-ink that can deliver oxygen to 3D printed tissue cells

- What are the characteristics of a well-formed 3D printing photosensitive resin material?

- What is the difference between industrial 3D printers and home 3D printers?

- Researchers use 3D printed MIMO antennas to improve 5G networks

- 3D Printed Luminous Characters Word E

- 3D Printing Personalized Bull Head Metal Jewelry

- 3D printing presses the fast forward button for China’s smart manufacturing

- 3D printing technology realizes hollow structure and conformal cooling

- The all-rounder of additive manufacturing design-nTopology

- Children’s 3D printed orthotics can reduce production time by 40%

- How high-performance material 3D printing is applied to the small batch production of terminal parts

- 3D Printing Halloween Bat Masks

- 3D Printing Large Car Models

- 3D Printed Fire-Breathing Dragon Metal Statue Model

- Coloring Human Heads Statue And Making Silicone Human Skin Masks

- 3D Printing Stainless Steel Chair

- 3D printed smartphone plug-in brings affordable vocal cord diagnostic tool

- What Material Is The Most Suitable 3D Printed Buckle Structure Assemblies

- Common Technology List Of Metal 3D printing

- 3D Printing Fine Electronic Mold Parts

- Arovo announces the start of the sale of 3D printed carbon fiber bicycles

- Exploration of Brake Caliper Design for Additive Manufacturing

- 3D Printing Nalakuvara Statue Model

- Multi-material selective area laser sintering 3D printing technology without large powder bed

- New flexible polymer materials for batch 3D printing

- 3D Printing Moon LED Lights

- 3D Printing Large Sculptures

- A high-quality part 3D printing process integrating mold material and metal injection

- 3D Printed Medical Sanitary Metal Masks Model

- Researchers use 3D printing to assemble nanoparticles into robust macrostructures

- On the road of additive manufacturing becoming a production-level technology, how can artificial intelligence make a difference?

- 3D Printing Chariot Model

- Insight into how SLM 3D printing technology makes pin-fin heat pipe heat exchangers

- Analysis of the characteristics of five commonly used 3D printing materials

- What is the application of 3D printing technology in the medical industry?

- The Process Of 3D Printing Spray Paint Coloring

- Digital casting is realized through the combination of sand mold 3D printing, simulation, and non-destructive testing

- 3D printed models that can help the disabled

- Can the printing accuracy of photosensitive resin SLA reach 0.05mm? What are the factors that affect the accuracy of SLA 3D printing?

- 3D Printing Large-scale Mr. Rabbit Model Sculpture

- Metal 3D Printing Mold Steel Parts

- The Industrial Applications Of Large Scene 3D Scanning

- 3D Scanning Of Artwork Is Popular In Europe And America

- 3D Printing Model Of PA12 Material

- The railway transportation industry uses 3D printing technology to enter the 21st century

- Economical and convenient 3D printing pure copper further opens up the wonderful manufacturing space of copper

- The latest application cases of 3D printing in aviation

- 3D Printing TPU Material Sole

- EOS and others use 3D printing technology to promote the development of glass fiber production

- The Application In The Film And Television Special Effects Makeup Industry

- Perspective on the status quo, challenges and next market pattern of metal 3D printing

- 3D Printing Donald Duck Statue Model

- The application and advantages of D printing technology in the mold industry!

- How to 3D print biosensors?

- The Application Exploration Of 3D Printed Bones In The Medical Orthopedics Field

- HRL laboratory develops a new method for 3D printed parts with fracture-resistant ceramic matrix composites

- 3D printing material: Somos® PerFORM nano-ceramic resin material that is strong and resistant to strong temperature of 260 degrees

- Big Shark Case 3D Printing Production

- New 3D printing technology can print 50 simulated steaks per hour

- 3D Printing Stainless Steel 304 Gear

- Analysis of the factors affecting the price of 3D printers

- 3D printed drones are swarming, why use 3D printed drones?

- Implement metal 3D printing procedures to improve efficiency

- Analyze the molding technology process of four types of 3D printing

- Using 3D printing to manufacture motorcycle display housings, shaping the future of mobility

- 3D Printing Handheld Electronic Machinery Housing

- Dual laser technology reduces the roughness of metal 3D printing by 80%

- 5 advantages of rapid prototyping in product design

- 3D Printing Custom Medusa Head For Bar Styling

- 3D printing TPU: a new flexible polymer material for batch 3D printing

- See how 3D printing can help optimize the design and optimization of the cooling water circuit of automotive electronic connector molds

- 3D Printing Wuhan Well-Known Building Hankow Customs House Model

- How to calculate the ideal process parameters of metal 3D printed parts

- 3D Printing Nylon Car Exhaust Pipe Model

- Finely Restore Details Of Ancient Cultural Relics

- From the green embryo to the final parts, the quality management issues in ceramic 3D printing

- Get a closer look at GE’s 3D printing of an integrated turbine cover with cooling channels

- Time-Saving And Efficient! 3D Printing Custom Chemical Fixtures Are Essential

- The next-generation smart glasses lens mass production technology is in place!

- Ultra-high-speed 3D printing Nexa3D joins Henkel Materials Platform and launches co-branded resin

- 3D printing enters the latest state of mainstream manufacturing technology

- Human bones may decipher how to extend the fatigue life of 3D printed lightweight structures

- The Casting Of 3D Scanning Case

- The whole process of 3D printing model cleaning and polishing

- 3D Printer Tutorial: Answers to Frequently Asked Questions for Users

- How to judge whether the price of 3D printer is suitable for this price?

- What are the benefits of 3D printing in car design?

- 3D Printing Black Photosensitive Resin

- New material: Polyurethane (PU) 3D printing material

- Zero-emission raw material production, the new 3D printing film comes out

- The Yingxian Wooden Tower Of Large Scene 3D Scanning

- A case to understand how material extrusion 3D printing technology realizes the added value manufacturing of advanced ceramic products

- Explain the design process of aviation fuel oil 3D printing heat exchanger in detail

- 3D Printing High Temperature Plastic Materials

- How does thermal aging affect 3D printed carbon fiber parts?

- Three-Dimensional Scanner Makes The Prosthetic More Warm

- How to see the impact of the rise of blind boxes on 3D printing?

- 3D printing is reshaping the motor stator windings of electric vehicles

- What is 3MF? Is it better than the STL format?

- 3D Printing Model Of Wuhan University School Gate

- Cases of 3D printing copper in electric vehicles, electric motorcycles, and traction motors

- 3D printed glass enables the integration of next-generation sensing, imaging and photonics

- Detailed introduction about FDM 3D printer technology

- Custom Trophy Model By 3D Printing

- 3D printed drones are swarming, the drones so far

- 3D Printing High-Precision Buddha Statues

- 3D Printing Pagoda Model

- What are the top ten applications of aviation 3D printing in the future?

- Factors affecting the price of 3D printing metal powder

- The difference and connection of 3D printing nylon PA6, PA12 and PA11

- Prospect analysis of microgravity metal 3D printing

- “Reverse” 3D printing method to make bone repair scaffold implants faster

- The Cultural Relics Of 3D Scanning

- 3D printed EEG equipment can help patients with spinal cord injury

- 3D printing carbon fiber, ceramic engine parts

- Harvard researchers develop eco-friendly shape memory 3D printing materials

- 3D Printing ABS Material Types And Performance And Application Summary

- Stilted Building Model By 3D Printing

- Everything you need to know about non-metallic 3D printing injection molds is here

- 3D Printed Transparent Medical Parts

- 3D Printing Puppy Model

- Introduction Of 3D Printing Thermoplastic Materials Such As PEEK And PEI

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- 3D printing molds relieve the production difficulties of forehead guns for emergency exits

- 3D printing manufacturing and traditional design manufacturing

- 3D printing improves the flexibility of electronic hardware development

- Introduction And Performance Of 3D Printing Nylon Glass Fiber Material

- The nine common photosensitive resin 3d printing materials

- Just 3 steps to get rid of the layer pattern of the 3D printing model you don’t like

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing improves copper metal heat exchanger performance

- The Archaeological Excavation Site Of Large Scene 3D Scanning

- What should I pay attention to when hollowing out light-curing 3D printing?

- Analyze the future of PEEK materials and domestic materials

- Gate design of metal castings based on 3D printing technology

- After 3D printing, 4D printing again?

- Print horizontally or vertically?

- PP 3D printing material family is filled with a new member for 3D printing of molten particles

- 3D Printing Highly Simulated Food

- my country’s first 3D printed impact turbine real runner was successfully developed

- 3D Printing Complicated Superalloy Parts

- Does 3D printing need to pay customs duties?

- Newly added 3D printing casting material—Introduction to 3D printing purple wax

- The future of 3D printing: see the new progress of additive manufacturing under the epidemic

- What Is Micro Manufacturing Technology

- 3D Printing Lightweight Aluminum Alloy Automotive Parts

- Explain six 3D printing post-processing methods

- 3D printing rubber material introduction

- Application Of 3D Scanning Technology In The Automotive Field

- The hidden dangers Analysis of 7 kinds 3D printer operation safety

- Large Sculpture Model 3D Printing Prototype

- Analysis of 3D printing ceramic materials

- 3D printing of continuous fiber reinforced thermoset materials

We have been trying to reduce the cost of 3D parts and did not expect that we can find a supplier which can provide the same Ultem 9085CG material but the price is only a quarter of the US supplier.

Much thanks to the PTJ team for helping us to prototype the car parts, Parts are finished quickly and look very nice! We definitely will do more business with PTJ Team in the future.

Great manufacturing time, cost and quality. We needed their help in a critical moment and they have always been eager to support us with all of out requests.

PTJ have produced top quality prints for us at very short notice and with great turn around times. They have provided us with a reliable service when we have needed it.

Both my recent orders arrived in the last few days.The PTJ Inc is amazing. I only now appreciate how delicate it is and some of the issues you had in printing it. The print was very well packed and it took quite a while to blow away the shredded paper. Many thankyous.

PTJ provided a fast and top quality service. The technician was brilliant, they were hugely supportive and the final outcome was incredibly detailed.

The package arrived today and everything in perfect. Great job with the models, and the packing was excellent. Everything arrived safely. I am very happy with your high level of customer service and quality. I will definitely be back with my next order. Thank you so much.

I’ll definitely come to you when/if I need more resin prints in future!I will also highly recommend your company to a dice-making group I am part of (with 10K+ members) for excellent quality products and customer service, so hopefully you’ll get more orders!

PTJ offers online 3D printing services for rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

Upload drawing files (PDF, DXF, IGES, STEP). You can easily register multiple drawings at once with the drawing file batch registration (EDI).

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

Quotation confirmation / order

The shortest estimate from drawing data. Check the quotation on a PC etc. and place an order (order).

* Estimates can be confirmed from the member-only management screen (PC, smartphone, tablet).

Started 3D Printing/Rapid Prototyping and production

After accepting the request, Rapid Prototyping and manufacturing work is started by a specialist in 3D Printing,Cnc Machining, prototyping, and equipment.

You can monitor the progress from your PC, smartphone, tablet, etc.

Finished product inspection / shipping

Processing and production completed. After a strict check, we will promptly deliver to the designated delivery destination. Please look forward to the arrival of the finished product.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.