Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

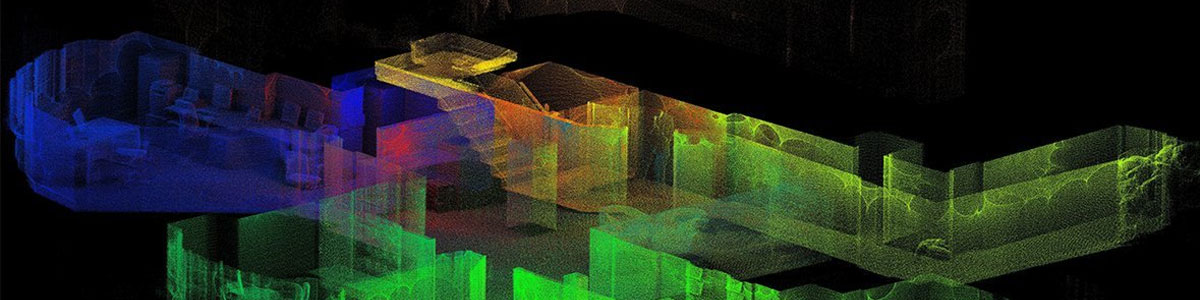

Industrial 3D Scanning

Faster speed, accurate data, texture information, light equipment, easy to carry

What Is Industrial 3D Scanning?

In the fields of automotive vehicles and parts, aerospace, rail transit, mechanical design and manufacturing, the mold opening, production, testing, and assembly of parts require extremely high accuracy. Industrial 3D scanners are used. Cooperating with the inspection requirements of the production line, it often has the effect of getting twice the result with half the effort

Table of Contents

The Application Of Industrial 3D Scanning Service

Application of 3D scanning technology in the automotive field

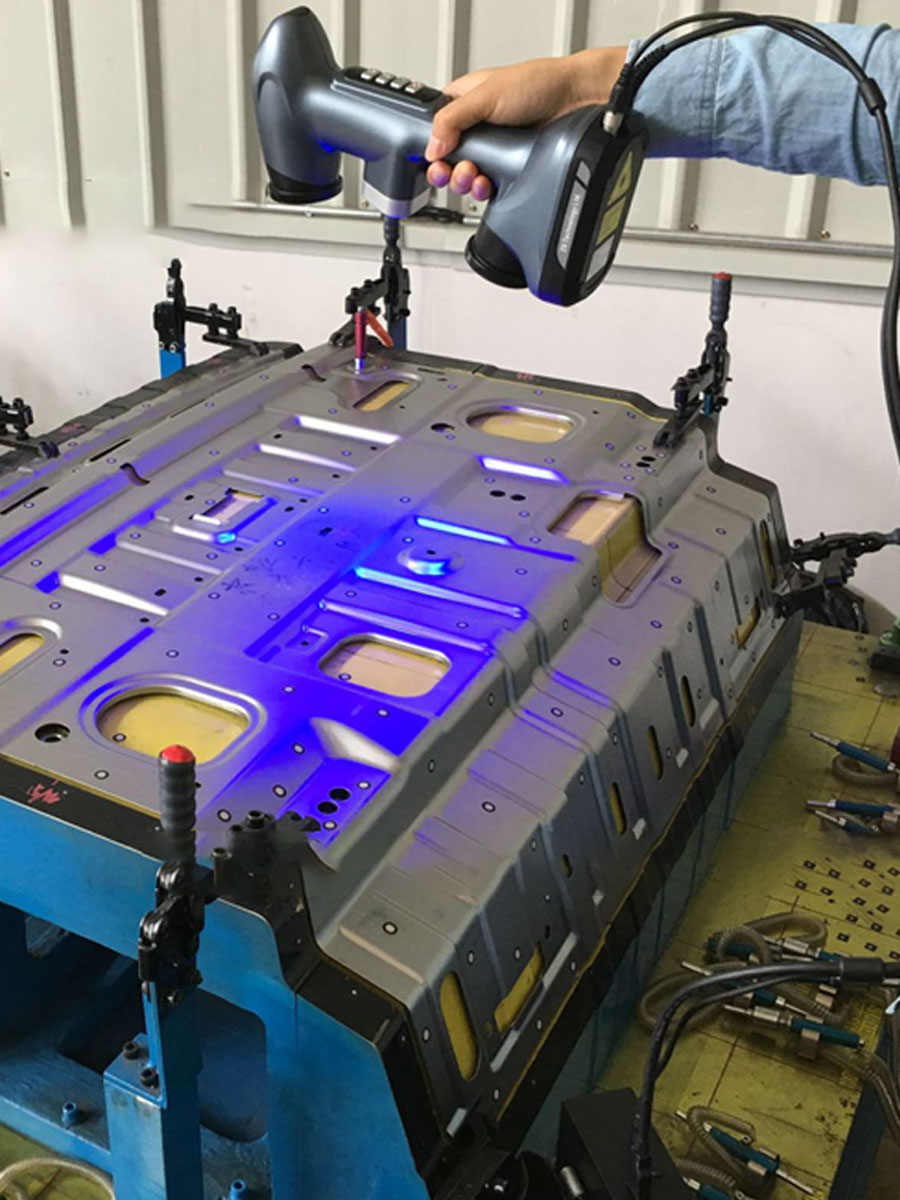

3D scanning technology has a wide range of applications in the automotive industry. It can easily and quickly obtain 3D data on the surface of the workpiece, and it is convenient to redesign the product appearance through reverse design.

Three-dimensional scanner makes the prosthetic more warm

No need to stick points, no need to touch the patient, you can quickly obtain accurate three-dimensional data of the leg, and then use the three-dimensional software to generate the curved surface to form a 3d digital model.

Finely restore details of ancient cultural relics

With current 3D scanning equipment, the accuracy and speed of scanned data have been greatly improved, and accurate 3D data can be quickly obtained without direct contact with the surface of cultural relics.

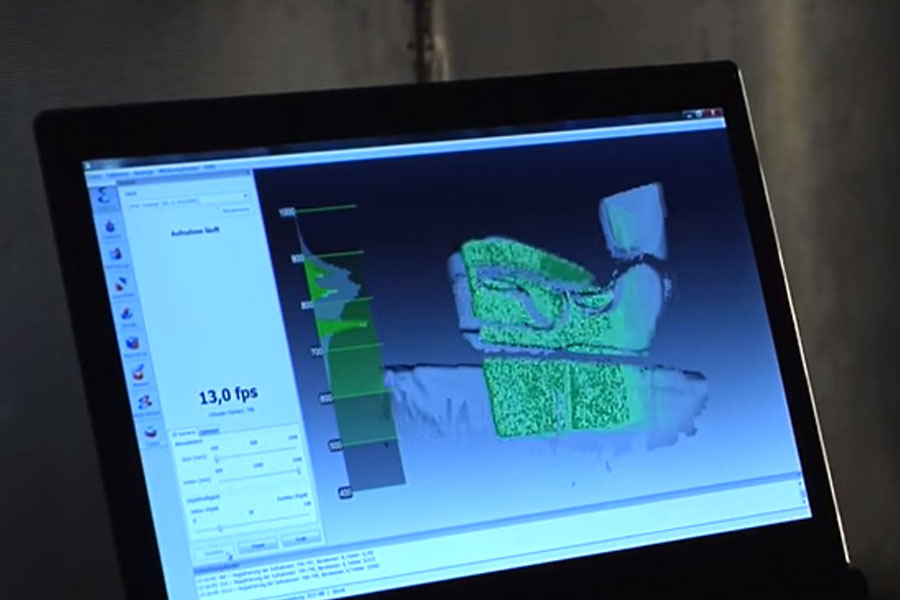

3D scanning car seat

When the car needed precise and realistic 3D car seat models for design and modification, they learned that a handheld 3D scanner would be the ultimate solution.

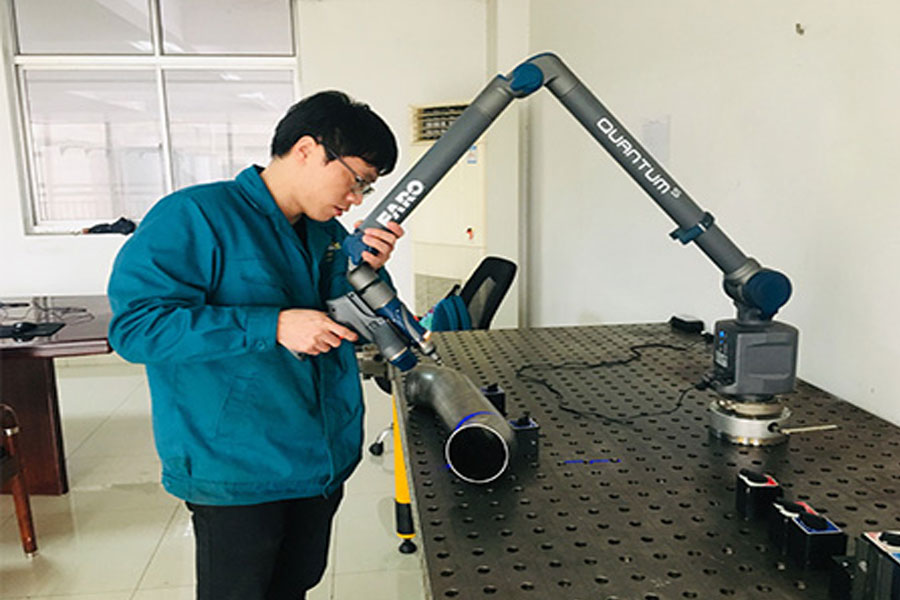

helps industrial inspection

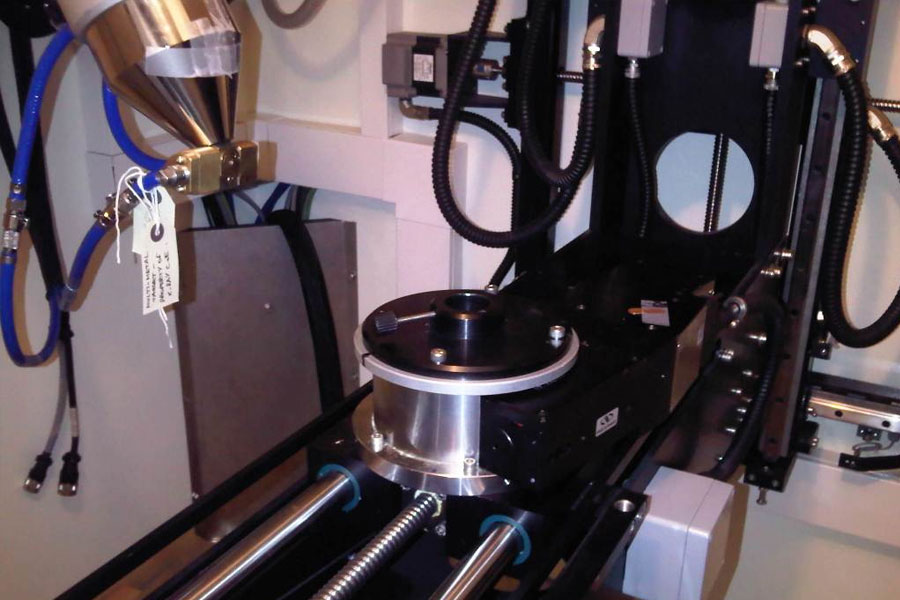

The measuring arm has a very high measurement accuracy. With the laser scanning head, it can perform point-to-point contact measurement and non-contact scanning measurement.

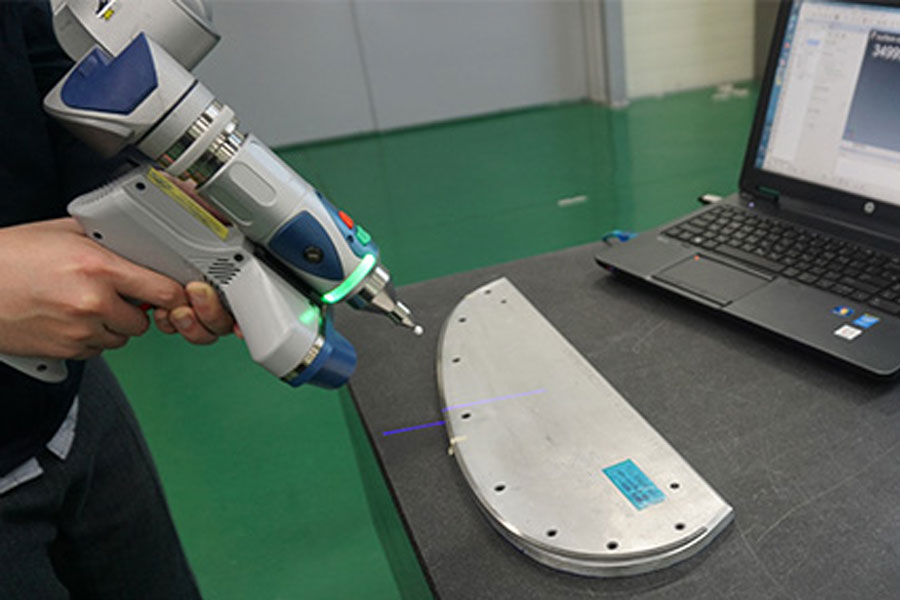

3D Scanning Aviation parts

Before an airplane takes off for the first time, it must go through numerous testing and certification procedures. The level of detail and the required processes are very demanding.

When To Use Industrial 3D Scanning?

For automotive, aerospace, machinery, electronics, energy and other types of companies, when doing product 3D scanning, reverse engineering, virtual assembly, online inspection, finite element analysis, etc., industrial 3D scanning is required.

Compared with traditional contact type 3D scanners, industrial 3D scanners do not need to be in contact with the scanned object, and have faster scanning speed, lower cost, and easier operation.

Industrial scanners can be divided into white light scanners, blue light scanners and infrared 3D scanners according to the different scanning methods. We will understand the scanning scene environment and data requirements according to the actual situation of the customer, and choose a comprehensive solution for you , Provide one-stop full-service.

The Application Direction Of Industrial 3D Scanning

- – The direction of cultural assets: As small as various cultural relics and artworks, as large as historical buildings, block buildings and even the overall urban environment, they can be scanned and digitized. As applications on cultural assets, they can be divided into the following types: (1 ) Record appearance; (2) Basis for future restoration; (3) Physical copy.

- – Product copying and reverse engineering: use the scanner to quickly obtain the three-dimensional data model or CAD drawing of the product, and carry out secondary development and design according to the model or drawing, to speed up the efficiency of product development and iteration.

- – Virtual assembly: Virtual assembly is an important part of virtual manufacturing. Using virtual assembly, you can verify the correctness of assembly design and operation, so as to find assembly problems early, modify the model, and visually display the assembly process . The premise of virtual assembly is to have three-dimensional data models of all products.

- – Finite element analysis: finite element analysis is the use of mathematical approximation methods to simulate the real physical system (geometry and load conditions) (scanning-modeling is the key to building a digital system). Using simple and interacting elements (ie units), a finite number of unknowns can be used to approximate the real system of infinite unknowns.

- – On-line inspection: Machine substitution is an inevitable trend in the development of the industry. Three-dimensional scanning is like the eyes of a robot, which can replace manual labor to complete product inspection more accurately and quickly, improve production efficiency and reduce the rate of defective products.

- – 3D printing & CNC processing: Whether it is 3D printing or CNC processing, having three-dimensional data is the first step, and three-dimensional scanning is an effective means to obtain three-dimensional data.

- – Online three-dimensional display: In a large number of video interaction and exhibition display applications such as film, animation, VR, AR, etc., having a three-dimensional model is a necessary prerequisite.

- – Delivery will be 1-7 days after the order is confirmed, and a variety of data formats can be provided.

3d-printing-china.com Case Studies

3D Printed Metal Rings And Precision Sleeves

3D Printed Luminous Characters Word E

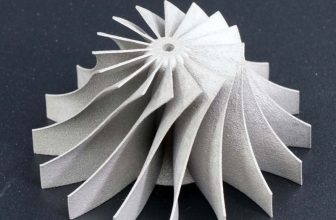

3d Printing Metal Turbine

3D Printing Pagoda Model

3D Printing Saxophone Mouthpiece

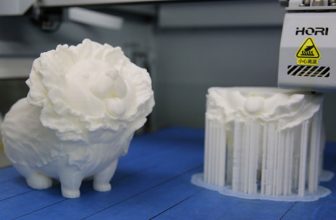

3D Printing Funny Small Dog As Cabbage Shape

3D Printing Fine Electronic Mold Parts

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.